| Rockbridge

Bloomery - Economy Norse Bloomery Furnace

|

This little iron smelting bloomery was inspired by the opportunity to work with Darrell Markewitz and Michael McCarthy at the Pre-Industrial Iron Symposium, Farmer's Museum Cooperstown NY in October 2004. Darrell constructed a very small and tidy Viking influenced bloomery that was a joy of sound and sight to operate (view Darrell's furnace).

Returning home Lee spied an old chimney flue liner in his blacksmithing ephemerata and decided to see how small and inexpensive a bloomery he could build. This is it. I'll try to give you enough details in what follows so that you can build one for yourself!

Construction

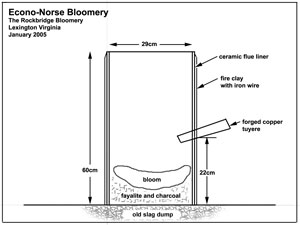

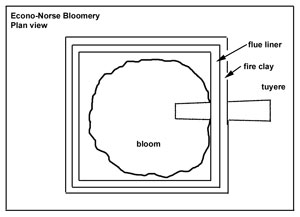

The bloomery stack is simply a single 2 foot tall ceramic chimney flue liner

available at your local brick store. This type of liner is a decent

refractory but will crack and fall to pieces if we don't do something to hold

things together. To prevent this tendency toward self destruction, Lee wrapped

the liner with rebar wire (chicken wire should be ok) and plastered over the wire with an inch

thick layer of fire clay mixed with charcoal dust and chopped straw just to hold things

together (fire clay is also available at the brick store) . The furnace was dried by burning a small fire both inside and

outside of the liner. Not much to it!

Build your furnace on sand, gravel, a slag pile, anything that will keep it dry and insulated from the moisture of the earth. Inside this furnace there will be 1300 degree C slag right down to ground level. Possibly the most effective type of insulation is that of the Japanese Tatara furnace which is built upon a deep bed of pounded charcoal and ashes.

Air Supply

Operating conditions in the furnace are controlled by monitoring the

charcoal burn rate. The actual type of air supply is not important. We use

a two stage vane compressor because we happen to have one but anything, a small

bellows, a squirrel cage fan, or a shop-vac should be fine.

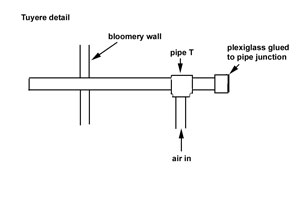

Air is supplied to the bloomery through a tuyere (pronounced with a southern accent - tweeeer) In these pictures we are using a copper tuyere which was made by forging a tapered tube from a bar of copper that was approx. 1/4 inch thick. The hole at the interior end of the tuyere is 3/4 inch across. The end outside the furnace has a removable sight glass through which you can watch the smelt progress. You will need to periodically remove the sight glass and clean the tuyere when it is blocked by slag.

Another option: Darrell Markewitz has had good luck using a black iron pipe. If anyone can figure out how to hand make a clay tuyere we would like to know how to do it, please email us.

Materials for the smelt

minimum 150 lbs. wood charcoal of any sort is fine. Have your

students, volunteers, people who just show up, break the charcoal into lumps

smaller than a walnut. Screen out the dust so that no one will have their hair

and eyes burned by flying ash during the smelt.

50-80 lbs Iron ore, roasted at a bright red heat but not hotter to drive off the water, and then broken to pea size. We don't bother to remove the dust. Everything goes into the furnace.

Operation

Preheat:

Slowly preheat the furnace for one hour with dry wood and no forced draft. A

faster heat up just encourages the self destructive tendencies of the ceramic

liner. Fill the furnace to the top with the charcoal you prepared. Turn on the

forced air (but still at a low blow rate) and let the bloomery heat up for 20

minutes. Refill the stack with charcoal as needed. The tuyere should be inclined

about 20 degrees from horizontal.

Smelting:

The bloomery is operated by adding equal weights of charcoal and ore to the top

of the stack. We add 4 lbs charcoal and 4 lbs ore whenever the level in

the stack permits. Adjust the air flow so that charcoal and ore are added about

every ten minutes (that is 24 lbs ore per hour) Three to four hours of operation

should produce a decent bloom.

Burn down:

Add another ten pounds of charcoal after your last ore charge and then let the

charcoal in the stack burn down to the tuyere level. Stop your air supply

and remove the tuyere. A copper tuyere might melt and should be pulled from

the furnace anytime air is stopped!!!

Extracting the bloom:

A large bloom will be present a few inches below the tuyere and will be stuck to

the walls of the furnace. You may be able to pry the bloom loose and remove it

through the top of the furnace. If not just pull the furnace over and push the

bloom and slag out of the bottom.

Results of the Rockbridge Bloomery smelt #55

Smelt #55 resulted in a bloom and furnace bottom that weighed 50 lbs.

The bloom weighed 24 lbs.

Total ore 80 lbs.

Total charcoal consumption 127 lbs.

Total time 6 1/2 hours preheat to removal of bloom.

Tuyere angle 22 degrees from horizontal.

Photo of bloom

Best of luck with your smelting. Please email feedback to

skip@wlu.edu