Bloomery iron fresh from the smelting furnace is called a

bloom. A bloom grows as an amorphous mass in a bowl of liquid

slag at the bottom of the furnace. When the bloom is removed

from the furnace it is covered with bits of slag and charcoal.

To work the bloom into useable iron, the smith must remove much

of the slag and charcoal from the bloom. During this process

the bloom is folded and welded to produce a uniform material

that is suitable for making implements.

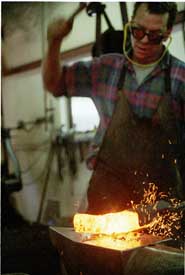

This bloom has been heated to almost a white hot temperature. At this temperature the iron is soft and easy to hammer.

The bigger the bloom, the harder it is to deform it with a sledge hammer. This bloom weighs about 13kg. The first thing we do is cut the bloom in half to make the rest of the hammering a little easier.

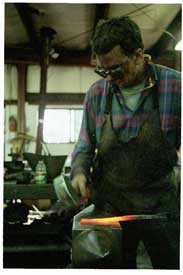

One of the halves of the bloom is reheated to a welding temperature and brought here to the anvil where we hammer it into a billet. Skip holds the uneven bloom firmly in a pair of tongs while Lee and Yates flatten the first two sides.

The surface of the bloom oxidizes each time it is reheated and the oxide falls to the floor and is wasted. The challenge is to shape the bloom with as little reheating as possible and minimize the loss of iron. Lee and Yates race against the fast cooling bloom. The sledges each weighing 12lb strike the metal every second for several minutes.

Here we see the bloom when it comes back from the fire, is held on its side on the anvil and the other two faces are hammered into rough shape.

The bloom is drawn out. From a roughly square form about

8 inches long, we make a billet that is a uniform 5 cm square

and 30 cm long. Yes, pieces of billets having this shape have

been found at several locations in europe. We try not to make

this stuff up!

While the bloom is being wrought to the size of a Roman currency bar most of the large cracks and imperfections will weld themselves together to form a strong uniform bar. However there are always those few spots that take special treatment. Here the tongs hold a small piece of bloom which will be welded over a crack that opened up during the intense hammering.

Lee doesn't think that the bloom is pretty enough so he puts it back into shape with a few sharp blows.

Making a currency bar from the billet...

The end of the bar is not very uniform so we remove it with a hot cutting tool. The removed piece will be reworked later in the day.

A suitable amount of iron is seperated from the rest of the billet.

This material will be deformed... more later

reducing from 2" by 2" to the size of a currency bar

Making everything tidy

the goofus pair holding the result