The Rockbridge Bloomery

Furnace Plans

Furnace #1

See plan full size

This was our first attempt at a bloomery furnace, that we used

for smelts 1 - 11. We never managed to make any decent iron in

it, but we made all our best mistakes here. Worst design flaws-

tapping the slag from the bottom, and having to dig the finished

contents out the top. 12" diameter, 26" shaft height

above tuyere. We started with iron tuyeres, went through ceramic

tuyeres, and finished with a water

cooled tuyere, which we have continued to use.

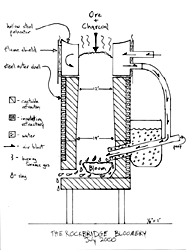

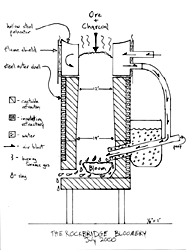

Furnace #2

See plan full

size

Armed with a little experience, and a little more historical

knowledge, we designed this furnace in stacked modules so we could

experiment with different shaft heights and tuyere heights. An

outer steel shell serves as the outer form for the insulation

and high temperature castable refractory interior. We increased

our diameter slightly to 14". In our very first smelt in

this furnace, we really cranked up the air in an attempt to make

cast iron by the Chinese model. Instead we got a 40

lb. bloom. This bloom was used to create "Nyamakala

I". From this smelt on, we have always produced forgeable

iron in decent quantity.

This furnace as drawn is referred to as 'tall shaft'. When the

upper 3' section is removed the furnace is referred to as 'low

shaft'.

Furnace Configuration #3

See plan full size

By smelt #20, furnace #2 had evolved into this lean mean iron-makin'

machine. The the mass of the tall shaft in furnace #2 changed

temperature only slowly which allowed us to learn how to control

the burn rate. But once we had learned what temperatures were

needed and how to adjust the air blast, we found the tall shaft

to be of no particular advantage.Adding a hollow preheater section

on top of the 'low shaft' furnace allows for a bit of saving in

charcoal. Smelts #20 to #27 all utilised this set-up.