|

Home

The Rockbridge Bloomery –

Reports

Smelting Enriched Bog

Ore in a Low Shaft Bloomery.

Jonathan Thornton, Skip

Williams and Aaron Shugar

Introduction:

During the 3rd

International Symposium on Early Iron, held at Eindhoven, Holland, I participated in an iron smelting experiment along

with Skip Williams, also of the United States,

and with the occasional assistance of other casual helpers. I am a

conservator and professor of conservation, as well as a blacksmith and tool

maker. Skip Williams has extensive experience in smelting iron using small

furnaces, though usually, these employ modern materials. The aim of our experiments

was to produce a good quality bloom based on the experience of Skip Williams,

but using technology that more closely approximated historic models than do

the majority of his smelts. The furnace that was built survived five smelts

in good condition, and did indeed produce a high quality soft-iron bloom with

some superficial steeling. The following description will make clear

both how the experiment attempted to duplicate the evidence of archaeology,

as well as how it intentionally diverged. Analysis of the resulting bloom was

carried out by Dr. Aaron Shugar, Mellon Professor

of Conservation Science here in the Art Conservation Department at Buffalo

State College.

Furnace: Furnace:

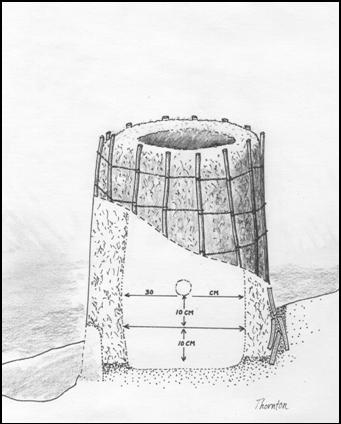

The furnace was constructed

from a sandy, iron-rich clay (loam) mixed with straw. This can be thought of

as a low-firing ceramic body. The role of sand and other inorganic “tempers”

in such a body, whether it is used for pots, tiles, or furnaces, is to

decrease shrinkage by reducing the ratio of the highly shrink-prone clay as compared

to other non-shrinking components. Grog (pre-fired ceramic) has also been

used in the composition of furnace material (Crew and Charlton 2005), and for

the same reason. The role of the straw is to increase the strength in

un-fired material by binding it together internally, and to provide vent

ducts for the escape of steam and other gases as the material converts into

ceramic. It may also play a role in stopping the propagation of incipient

cracks. This has been a common strategy in low-firing ceramics.

Examples of the material from the destruction of similar furnaces at Eindhoven show that the inner

sections are well supplied with empty tubes from the straw having been turned

to ash, while outer sections contain straw that is not even charred. As would

be expected, the furnace fragment exhibited a dark grey

reduced-iron zone on the interior, and an abrupt transition to red oxidized

material on the exterior zone.

The site chosen for the

furnace was near a previous furnace that was mostly demolished. The remains

of this furnace formed a small mound, into which the circular shape of the

new furnace was marked out and excavated into the slope to a depth of only a

few centimeters at the front where the tap arch would be located. The

bottom of the hearth was roughly leveled and compacted.

The furnace material were

prepared by treading the damp loam and additional water with the chopped

straw (using bare feet), until it had a firm, plastic consistency. This

material was formed into ovoid “bricks” of about the size and shape of small

loaves of bread. These were then used to build up the superstructure of the

furnace. The areas opposite the tap- arch that were excavated into the mound

were lined with fragments of fired pots so that the wet ground would be

better insulated from the furnace.

The interior space of the

furnace was reserved and determined by a bundle of reeds that the museum had

available for thatching purposes. Owing to the natural taper of individual

reeds, the bundle also tapered when the bundle was set upright on the cut

ends. This provided an advantageous inward taper to the smelting

chamber. Reed impressions have been noted before in archaeological

investigations of furnaces (Crew and Charlton 2005). It had been supposed by

these authors that the reeds had been burned out prior to heating the

furnaces. We may have tried this also had the museum not wanted them

returned. As it turned out, the reeds were easy to pull out once the furnace

had become somewhat firm. This was done by pulling the center reeds out

first, and working to the outside. Once a furnace has been fired, it is

difficult to tell whether reeds were removed intact or by fire, except

perhaps by smearing of the impressions.

Although the interior space

was reserved by the reeds, the exterior of the wet furnace material did not

support itself well as the furnace gained in height. It appeared to exhibit

the property known as thixotropy- that is that it

flowed under applied force (such as patting and kneading). Some Eindhoven participants solved

this problem by building a wood-fire in the interior, so that the lower

portions would dry and become more firm as construction proceeded. As the

main fabricator of our furnace, it occurred to me that an outer frame-work

composed of handy and nearby willow shoots, would provide enough support to

allow construction to the full intended height. Unbeknownst to me at the

time, archaeological evidence has shown similar small “post holes” around

excavated furnaces (Crew and Charlton 2005). This was an interesting example

of convergent problem solving and the value of experimental

archaeology. This wicker-work cage was made by sticking the willow

shoots into the ground around the outer circumference, angling them inwards, and tying them together with cord as the

furnace gained in height. They supported the furnace well, and were clipped

off flush with the top of the furnace after the final course of bricks was

added, the reeds removed, and the outer and inner walls smoothed.

Interestingly, the wicker-work survived all four smelts mostly intact, a

testament to the insulating qualities of the furnace walls.

The tap arch was marked out and thinned on

the exterior front of the furnace (opposite the mound) and the tuyere hole

was located above and on the side, ninety degrees from the tap arch. Skip

Williams had previously determined that furnaces tend to thin out near the

tuyere. It was his intention to start with a thinned wall in this location so

as to keep that area somewhat cooler, and to prevent the bloom from adhering

to the tuyere. This was thinned from both the outside and the inside surface

by reaching down into the furnace. It should be noted that all areas of the

interior were reachable, aiding in modifications and subsequent repairs. The tap arch was marked out and thinned on

the exterior front of the furnace (opposite the mound) and the tuyere hole

was located above and on the side, ninety degrees from the tap arch. Skip

Williams had previously determined that furnaces tend to thin out near the

tuyere. It was his intention to start with a thinned wall in this location so

as to keep that area somewhat cooler, and to prevent the bloom from adhering

to the tuyere. This was thinned from both the outside and the inside surface

by reaching down into the furnace. It should be noted that all areas of the

interior were reachable, aiding in modifications and subsequent repairs.

Cracks did develop however- in

particular, two large vertical cracks opposite each other- one on the tap

side, and one on the back. This was alarming enough during the first smelt,

that an iron hoop was quickly fashioned and forced down over the furnace exterior

to prevent collapse. These large cracks were patched after the first smelt

and never opened up again. The interior of the furnace remained essentially

intact except around the tuyere area, which spalled

and thinned further. This was not repaired as it seemed to be what the

furnace “wanted to do,” in confirmation of the reasoning behind thinning this

area at the outset.

Before use, the furnace was

dried and pre-heated by building a wood fire in the interior and burning it for

a few hours. During this process, the entire furnace began to steam as water

was driven off by the internal heat.

Ore:

The ore that was available to

the Endhoven participants was a bog ore from North

Western Germany. Previous analysis carried out by Dr. Arne Espelund indicated that most samples were of relatively

low iron content, and high in phosphorus. Based on the quantity of iron that

would necessarily be reacted with the silicates and end up as slag, it was

his prediction that this ore should not produce much if any iron, despite

previously reported success.

As a means of enriching this

bog ore, Skip Williams requested a supply of hammer-scale (magnetite). This

was supplied by the museum. During the two successful smelts, the hammer

scale was mixed with and charged with the roasted bog-ore in a ratio of 50/50

by weight to simulate an ore of approximately 80% FeO

content. Whether or not such “enriching” materials would have been available

historically, or whether they even needed to be, is open to conjecture. It

does seem likely that all high-iron content waste from bloom consolidation

and smithing would have been recycled into a furnace, as perhaps also would

magnetic slag. Since most blooms would have been smithed

into useable bar iron on the site of the bloomery, the waste from smithing

would have been available to early smelters. The loss of weight from the

bloom to bar iron has been reported as high as three quarters of the original

bloom, to as low as twelve percent (Craddock 1995). In our experimental

smelts, the spongy reduced iron towards the outer portion of the bloom was

knocked off with a small hand hammer before consolidation of the remaining,

densely metallic bloom. This material too, could have been easily

recycled. Also, the bog ore supplied to us was not sorted according to

density and apparent quality, but seemed variable enough that careful

selection might also have increased the iron content.

Fuel:

In common with all

participants, the charcoal supplied was a hardwood charcoal produced using

traditional methods in Germany.

This was highly variable in the size of pieces. We reduced the size by

stamping on it and chopping it with shovels, then we sifted out the fine

particles (“fines”) using a coarse screen. Charcoal size is relevant to burn

rate, and it was the intention of Skip Williams to have charcoal chunks that

were no larger than a few centimeters, and without the fines that cause

excessive and annoying sparks. During the sorting process all pieces of

unburned wood as well as stones were discarded.

Draft:

Participants in the symposium

used a variety of blowing apparatus, both mechanical and human-powered. We

used an electric blower fan, reasoning that a blast is a blast, and having no

available slaves (or bellows for that matter). The air was forced through a

T-shaped piece of pipe so that the interior of the furnace could be observed

through a glass port in line with the tuyere. This arrangement also allowed

us to reach through the tuyere with a rod and clear slag drips from the

interior end when it seemed on the way to becoming clogged.

Tuyere:

In his previous smelts, Skip

Williams has used a tuyere that projects somewhat into the interior of the

furnace. He brought to the symposium a copper tuyere forged from a heavy

piece of copper plate with the intention of using this during the

experiments. This was used during the first smelt with success. The use of a

copper tuyere dictates that the blast must remain running during an

unclogging operation, or the end will quickly melt off. For this and other

reasons, we decided to fabricate a ceramic tuyere that could better withstand

smelting temperatures. Dry, white-firing primary-type clay was used for this,

mixed approximately 50/50 with sand, and kneaded to a plastic “potting”

consistency with water. I started fabrication by penetrating both thumbs into

the center of a ball of clay, then pinching out a tube of clay with my thumbs

still inserted- essentially creating a double “pinch pot.” I then inserted a

straight willow stick approximately the width of my thumbs, and increased the

length of the tuyere by working it out along the stick. I placed this over

the opening of the furnace that was still hot from the first smelt and

allowed it to become firm. Once it had done so, I tapped the projecting end

of the stick on a hard surface so that the tuyere would slide down and off. I

made two such refractory ceramic tuyeres during the

experiments. The first of these was pre-fired, but proved to be too short

(particularly after it was accidentally stepped on during the frenzy

attending the extraction of the first bloom). It was quickly replaced with a

longer one that was installed without pre-firing. This second tuyere survived

subsequent smelts essentially intact, with only slight vitrification

and slag erosion at the tip.

The tuyere was inserted at an

angle of approximately 20-25 degrees above the horizontal, an angle arrived

at by folding a piece of paper diagonally (45 degrees) folding it diagonally

again, and comparing the slope as the tuyere was sealed into the hole created

for it using soft loam. The end of the tuyere projected into the interior of

the furnace roughly as far as the original interior of the furnace before it

was thinned in that location. This ensured that the blast would penetrate

into the interior of the furnace, but that the tuyere would not be crushed or

clogged by the constantly settling charge. The blower pipe was inserted

into the flared end of the tuyere, and also sealed with loam.

Smelting:

The bottom of the furnace was

filled with charcoal fines to a depth that was just a few centimeters below

the tuyere opening. The fines would essentially provide an insulating support

for the slag and bloom. This bed would also be easy to excavate during bloom

extraction.

Hot coals were added, and the

charcoal fire started. Once it was burning well, the blast was turned on, and

the furnace filled with charcoal. With the furnace full of incandescent charcoal,

the charging was begun. The intent was to keep the furnace full of burning

charcoal and ore so that immediately after fresh charging, it was slightly

mounded above the top of the furnace. The ore was charged in back of an

imaginary line bisecting the circular top, and opposite the tuyere. In Skip

Williams’s experience, this allowed the ore to settle towards the tuyere as

it tends to do, but not so far as to block it with the bloom. The intent is

the produce a bloom in the center of the furnace. Charging with

charcoal and ore was repeated when the charge had sunk enough to accept a

fresh charge. In general, the furnace was charged with equal weights of ore

and charcoal at each charging, though the fuel-to-ore ratio was increased a

few times when, according to the experience of Skip Williams, the furnace

appeared to be burning too slowly. During most of the smelt, the furnace was

charged every fifteen minutes. The smelt was continued until the starting

quantities of ore had been exhausted, though further charges of charcoal were

burned after that, and before bloom extraction.

Tapping and extraction: Tapping and extraction:

The blower was turned off, and

a rod was driven through the top of the tap arch until the pockets of slag

were found. This drained off into a previously prepared depression that had

been lined with a layer of charcoal fines. The slag was fully molten and

fluid, running out into quickly cooling blocks that were removed with a

shovel. This slag proved to be weakly magnetic, probably owing to the inclusion

of particles of reduced iron and/or magnetite. When the slag had been

depleted, the tap arch was gradually enlarged with a shovel and the location

of the supposed bloom was undermined to create a cavity that it could drop

into. During this process, incandescent charcoal poured down around the sides

of the bloom, and was also shoveled out. Finally, with the assistance

of a large wooden pole that was banged down on the top of the bloom from

above, the bloom dropped into the undercut cavity and was extracted through

the tap arch. The first smelt produced a solid bloom that was immediately cut

into two pieces with an axe and sledge. The second and larger bloom was

consolidated intact: First the spongy iron and slag was knocked off the

exterior surfaces with a hand hammer, and then the solid lump was

hammer-consolidated on a stump using heavy sledges (triple striking at one

point).

Magic:

On an anthropological note, I was struck by

how similar the tapping and extraction process was to childbirth: The slag

pours out (“water breaks”), the tap arch (birth canal) is gradually enlarged,

the bloom descends (the birth canal) and is finally extracted (not without

difficulty) in an atmosphere of excited expectation and purposeful

preparation and activity. This could not have been lost on ancient people and

would no doubt have influenced and increased the significance of attendant

ritual and “magic.” We ourselves decorated the tap arch with a vulval symbol, fashioned a small Venus figurine from the

tuyere clay, and poured an “offering” of duty-free whiskey into the furnace

before charging began. It should never be forgotten in interpreting ancient

sites that such things were equally “practical” to early technologists as ore

and fuel quality or furnace design. On an anthropological note, I was struck by

how similar the tapping and extraction process was to childbirth: The slag

pours out (“water breaks”), the tap arch (birth canal) is gradually enlarged,

the bloom descends (the birth canal) and is finally extracted (not without

difficulty) in an atmosphere of excited expectation and purposeful

preparation and activity. This could not have been lost on ancient people and

would no doubt have influenced and increased the significance of attendant

ritual and “magic.” We ourselves decorated the tap arch with a vulval symbol, fashioned a small Venus figurine from the

tuyere clay, and poured an “offering” of duty-free whiskey into the furnace

before charging began. It should never be forgotten in interpreting ancient

sites that such things were equally “practical” to early technologists as ore

and fuel quality or furnace design.

Furnace repair:

Before each smelt the tap arch

was rebuilt with loam “bricks” and sealed to prevent gas leaks from

occurring. No other repairs were made to the lining of the furnace.

Product:

Of the four smelts, two

produced successful blooms. Both used bog ore enriched with magnetite. These

blooms were roughly lens shaped (plano-convex),

with the more convex surface oriented downwards in the furnace. It was this

convex surface which was less densely metallic, including more slag, imbedded

charcoal, and casts of charcoal pieces that had burned to ash. The flatter

and uppermost surface was densely metallic by comparison. The first bloom

weighed seven kilos and was cut into two major pieces. The second bloom was

sectioned through after I returned to Buffalo,

New York using an industrial power

hacksaw. Interestingly, large interior voids in this bloom were mostly empty

rather than being filled with slag as expected. The bloom was easy to cut and

did not destroy the hacksaw blade. Spark testing on a grinding wheel showed

the starburst, secondary sparking characteristic of high carbon material,

specifically steel, on some exterior zones, but the interior produced the

long, non-branching sparks typical of wrought iron. The slag was a dense,

black fayalite-type slag with a metallic sheen.

Interior voids showed tabular crystals, most likely Wustite

growing on the interior surfaces, surrounded by glassy vitreous material.

Analysis:

Metallographic

Two areas of the bloom were

identified as wrought iron and steel respectively based on spark testing

using a grinding wheel. Small sections were cut from these areas of the

bloom, mounted in epoxy resin, and ground and polished to 1μm with

diamond paste. The samples were etched in 2% Nital

for 30 sec to enhance the microstructure of the metal. Reflected light

microscopy was used to look at the microstructure and the entrapped slag for

identifiable features and to better understand the blooms production.

All of the structures seen

were typical of slow cooling, most likely a result of the heat-holding

ability of the large iron mass. The “wrought iron” section (Sample 1), taken

from the top part of the bloom showed a structure consisting almost entirely

of ferrite, with slag inclusions of variable size. In some areas close to the

surface, a fine dendritic pearlite

formation surrounded by a ferrite matrix was observed. The “steel” section

(Sample 2), taken from the underside of the bloom showed a mixed structure of

pearlite and ferrite grains surrounded by

relatively larger slag inclusions. In some areas of this section, the pearlite content was approximately 50%, indicating

estimated carbon content for the entire area of about 0.4% carbon. Also of

interest was the widmanstätten structure of the pearlite in some areas. This structure has been observed

in experimental blooms by other researchers (Salter and Crew 1997), and is

also generally associated with slow cooling. The steel region, while a hypoeutectoid steel,

would still be possible to harden by non-equilibrium heat treating

(“quenching”). The slags were fayalitic

throughout, with a dendritic growth of wustite formed in a fayalite

matrix on some of the larger inclusions.

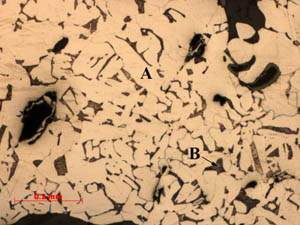

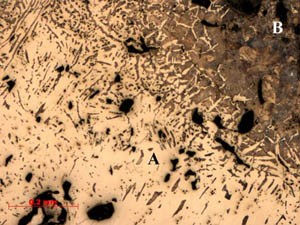

Figure

1: Sample 2: This sample is more

complex than sample 1 with several areas of varying compositions. This area is a hypo-eutectoid steel with a

majority of large ferrite grains (A) and smaller pockets of pearlite (B). Figure

1: Sample 2: This sample is more

complex than sample 1 with several areas of varying compositions. This area is a hypo-eutectoid steel with a

majority of large ferrite grains (A) and smaller pockets of pearlite (B).

click on images to view at full size

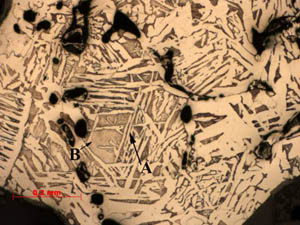

Figure

2: Sample 2: This area is

comprised of both primary and secondary widmanstatten

ferrite growth (A) and pearlite (B). This unique structure forms from austenite

at relatively high temperatures and consists of ferrite and pearlite. The

cross-hatched appearance is due to the ferrite having formed along specific

crystallographic planes. Figure

2: Sample 2: This area is

comprised of both primary and secondary widmanstatten

ferrite growth (A) and pearlite (B). This unique structure forms from austenite

at relatively high temperatures and consists of ferrite and pearlite. The

cross-hatched appearance is due to the ferrite having formed along specific

crystallographic planes.

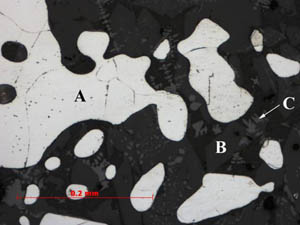

Figure

3: Sample 2: A third area within sample 2 is a dense fayalitic

slag region. The underbody of fayalite (B) has overgrowth of wustite

(C) and ferrite iron (A). It is a low carbon region of this sample. Figure

3: Sample 2: A third area within sample 2 is a dense fayalitic

slag region. The underbody of fayalite (B) has overgrowth of wustite

(C) and ferrite iron (A). It is a low carbon region of this sample.

Figure

4: Sample 1: This sample is composed of porous ferritic

iron (A) with smaller pockets of dense fine pearlite

(B). Figure

4: Sample 1: This sample is composed of porous ferritic

iron (A) with smaller pockets of dense fine pearlite

(B).

Figure

5: Sample 1: Close up of the finely dispersed pearlite

with some intergranular ferrite. The sample is a hypo-eutectoid steel. Figure

5: Sample 1: Close up of the finely dispersed pearlite

with some intergranular ferrite. The sample is a hypo-eutectoid steel.

X-ray fluorescence

The polished sections were

analyzed using X-ray fluorescence. A Bruker ARTAX

u-XRF was used for the analysis. The system is equipped with a helium purge

and variable collimators from 0.2 mm to 1.5 mm. For this study a 0.65 mm

collimator was used and the machine was run with the helium purge to help

identify any lighter elements that might be preset in the metal.

Samples were run for 90 sec at 50 KeV and 700 uA. The ARTAX does not presently have a fundamental

parameters programming which would give relative values for those elements

present in the metal. This machine must be calibrated for specific compositional

analysis to give any real indication of compositional values. It is

unpractical to do this for each ‘unique’ material that comes into our lab,

but the resulting spectra accumulated from the analysis can be interpreted

qualitatively, and as such, the particular elements present in the metal can

be identified and roughly estimated for their concentrations as major, minor

or trace levels.

Analysis showed the iron to be

relatively pure with limited trace elements including Copper, Arsenic and

nickel. Interesting, the nickel only appears in the pearlite

phase of the metal. No obvious explanation presents itself.

The individual smelts:

Four separate smelts were

carried out using this furnace. The first smelt proceeded essentially as

described, and produced a good bloom. The second was carried out at the

request of, and with the assistance of Arne Espelund,

to test his hypothesis that iron could be smelted from bog ore and iron-rich

slag. This smelt failed to produce good malleable iron, and will be left for

Dr. Espelund to describe. The third smelt was the

more successful of the two carried out according to the description already

given. The last and final smelt was carried out with Thijs

van de Manakker, in order to test whether or not

good iron could be produced from the German ore using a furnace that had

already proven successful. It failed to produce a bloom of malleable iron.

The first smelt:

This initial experiment was

carried out on Friday September 15th, commencing with ore charging

at 15:15 and ending at 22:11, for a final duration of 7 hours.

Charcoal was consumed at the rate of 4kg/hr, with 28 kg consumed during the

actual smelt. The furnace was charged with ore at the same time that charcoal

was added. The ore used was a 50/50 (wt.) mixture of the German bog ore and

hammer scale. The final bloom weighed 8 kg.

Third smelt:

The third smelt was carried

out on Sunday September 17th, with the first ore added at 10:30, and the bloom extracted soon after 16:20, for a duration

of almost six hours. The same ore mixture was charged at a rate of 6kg/hr.

Total charcoal consumption was 36kg. Ore

consumption was 34kg. The final bloom weighed 10kg after consolidation.

Discussion:

It seems clear that the

decision to enrich the bog ore with magnetite hammer scale largely accounted

for the success of the two smelts which produced good iron in quantity. The

third smelt though seems to have benefited from other factors. It was faster,

consuming charcoal more quickly, and since the ore was always charged in

equal parts by weight with the charcoal, the whole smelt was of shorter

duration. It seems likely that the fire burned faster and hotter due to the

furnace already being hot and dry at the outset. Efficiency was probably also

improved by the patching of cracks after the initial smelt. If the point of a

shaft furnace is to contain reducing gasses for a longer period of reaction

time, then large cracks shooting out blue flame would seem to be a likely

explanation for reduced efficiency. There was no apparent side-wall

leakage during the third smelt. The yield was a remarkable bloom of ten

kilograms, a size and weight from 34 kilograms of ore that shows particularly

efficient extraction for a furnace of this type- at least in modern times.

References:

Craddock, Paul. 1995. Early

Metal Mining and Production. Washington DC:

Smithsonian Institution Press.

Crew, P. and Charlton, M.

2005. “The anatomy of a furnace.” Conference paper presented at Metallurgy-a

Touchstone for Cross-cultural Interaction. London:

British Museum.

Salter, C. and Crew, P. 1997.

“high phosphorus steel from experimentally smelted

bog-iron ore.” In Early Ironworking in Europe

and international conference at Snowdonia National

Park Study Center, Wales.

|