The Rockbridge Bloomery - Reports

Building a

Teeny-Tiny Bloomery

Skip Williams March 20, 2006

March 20, 2006

This is my first step toward developing a tiny bloomery that can be used as a

teaching tool in a small academic laboratory, or with some improvement and a

lot of experience, it should be suitable for assaying unknown ores.

A Little Information about the

Design.

Starting with all of the usual measurements from the Coated-Tyle furnace, I

built the tiny furnace from kaolin and cellulose but reduced most of the

measurements to 1/6th of the normal cross section. The diameter of the round

stack was 5 inches compared to the 11 inch square tile. The shaft of the

bloomery was approximately 12 inches tall. The tuyere diameter was 3/8 of an

inch at the small end. The charcoal burn rate is equally reduced to about 4

lbs. per hour. This may be a great waste of time if you want to make big iron

but this is a great way to test a bunch of ideas about how shaft height, tuyere

materials, etc., effect the operation of a bloomery.

The sloped clay box on the right of the stack is an air chamber, the idea being adopted while watching Michael McCarthy build a Japanese Kodai. The air chamber is fed from a blower in the back. It houses the tuyere, and has a removable clear Plexiglas top through which I can watch for slagging and also rod-out the tuyere. The round holes visible in the air box are plugged with clay bits to adjust the air rate. I think the total bloomery weighed only 12 lbs.

The

tiny bloomery, I call it the Ocarina, kicked butt. From only 1.5 lb of ore we

made a bloom of 1.5 lb. OK there was a bunch of wall stuck to the bloom but the

crazy thing was that the bloom looked pretty much like a regular (big) bloom

except that it was tiny. Is it iron on top, slag on the bottom, just like it

should be.

The

tiny bloomery, I call it the Ocarina, kicked butt. From only 1.5 lb of ore we

made a bloom of 1.5 lb. OK there was a bunch of wall stuck to the bloom but the

crazy thing was that the bloom looked pretty much like a regular (big) bloom

except that it was tiny. Is it iron on top, slag on the bottom, just like it

should be.

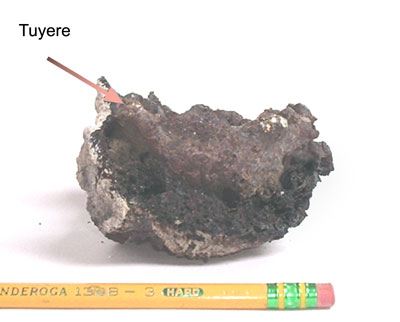

The picture to the right shows the bloom with an

indication of the direction that the tuyere was blowing.

The bloom turned out to be not as good as it looks though. After knocking off

the slaggy bits we were left with just a crown of

iron, just blobs and foils really.

I should tell you a little about how I prepared the

bottom of the furnace bowl because this might be useful someday. Normally we

pack the bottom of the furnace with charcoal fines and allow the slag to create

its own bottom by running through the fines and freezing wherever the

temperature is low enough for solidification. Since we are working

with such a tiny amount of ore, I thought that it would be good to choose a

depth below the tuyere where the slag could go no farther. Figuring that about

one inch below the center of the tuyere would do the trick, the furnace was

preheated to dry it, and then I added fines to fill up bottom space and then

put in a layer of ashes from the wood stove, packed it all down with a stick

and let her rip. Whether by intent, or by luck, the bottom of the bloom still

had the shape of the ash bed when we pulled it out. This technique culled from Biringuccio and Evenstad will probably become important

when we start playing with liquid iron products, but who knows, choosing a

place for the bloom to grow in front of the tuyere might be important for

controlling carbon content or bloom quality and yield in a full size bloomery

also.

Here

is the tiny bar that Lee forged up from the bloom. It weighs only 2 ounces (60

grams)! Just enough to make a smallish pen knife and a good first try with the Teeny-Tiny

Bloomery. With some luck this tiny smelter will become useful for quick demos and

maybe assaying. We'll see.

Here

is the tiny bar that Lee forged up from the bloom. It weighs only 2 ounces (60

grams)! Just enough to make a smallish pen knife and a good first try with the Teeny-Tiny

Bloomery. With some luck this tiny smelter will become useful for quick demos and

maybe assaying. We'll see.

Skip Williams

The Rockbridge Bloomery